Welcome To Bright Metal Works

Bright Metal Works is currently leading manufactures of marine propellers in Kerala, India.

MOULDING

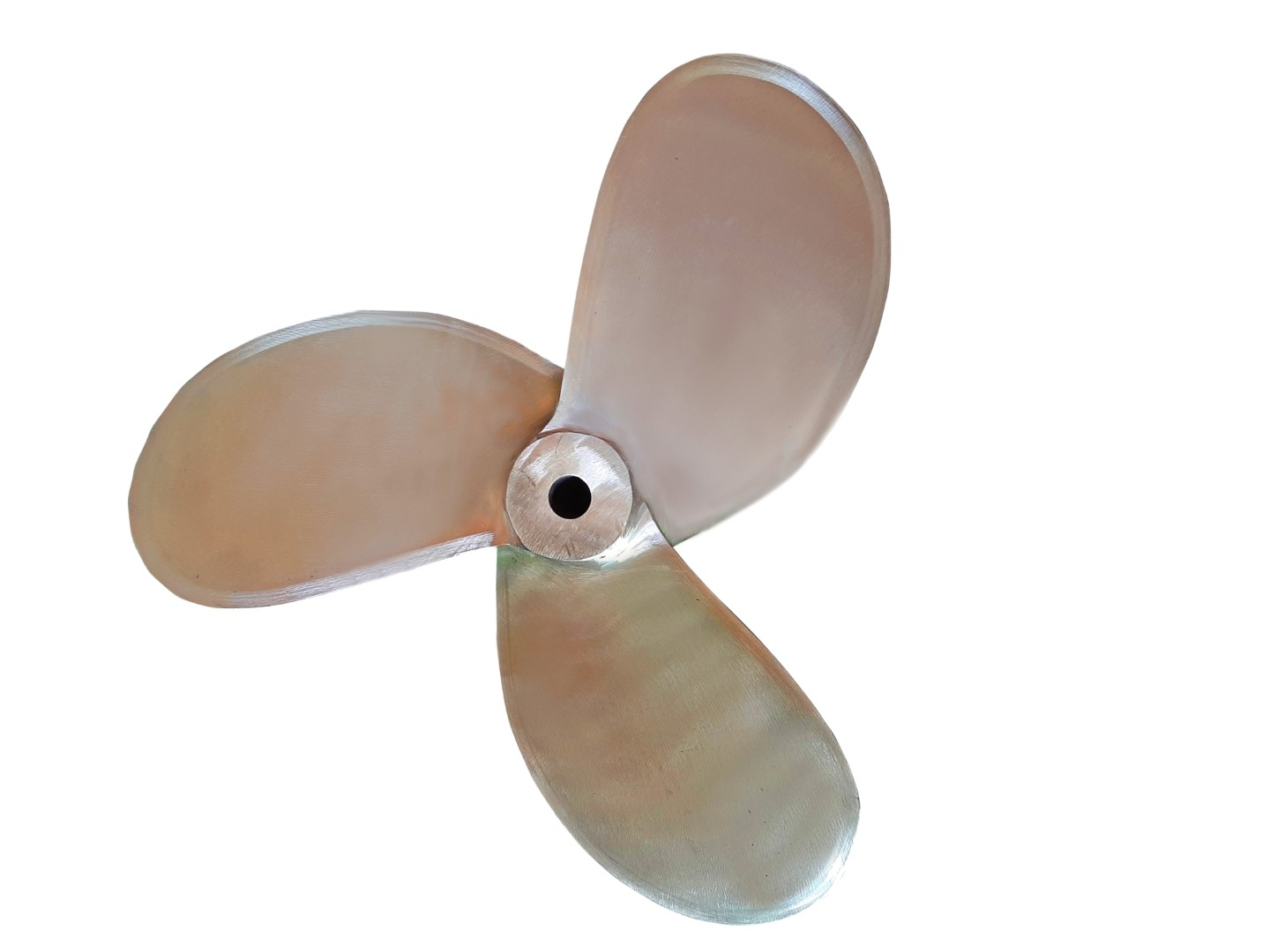

Our foundry manufactures 3, 4 bladed propellers from 20 inch diameter up to 65 inch varying in terms of weight based on engine capacity, rpm, gear ratio etc., keeping up with standards and various class establishment standards, as per requirement.

CASTING

Standard material of manufacture of boat propellers are Gun Metal, Manganese Bronze and phosphorus bronze mixture. Chemical and mechanical peculiarities of the alloy made in our foundry, makes the propeller stronger and more efficient.

MACHINING

Our propellers are hand-crafted, finished and balanced by a team of dedicated, skilled and specially trained staff.

SKILLS

To work with various types of propellers and related components, such as a 4-blade propeller, a cutlass rubber bush, or a 3-blade propeller, you need a diverse set of skills and knowledge areas. Here’s an overview:

Our Works Portfolio

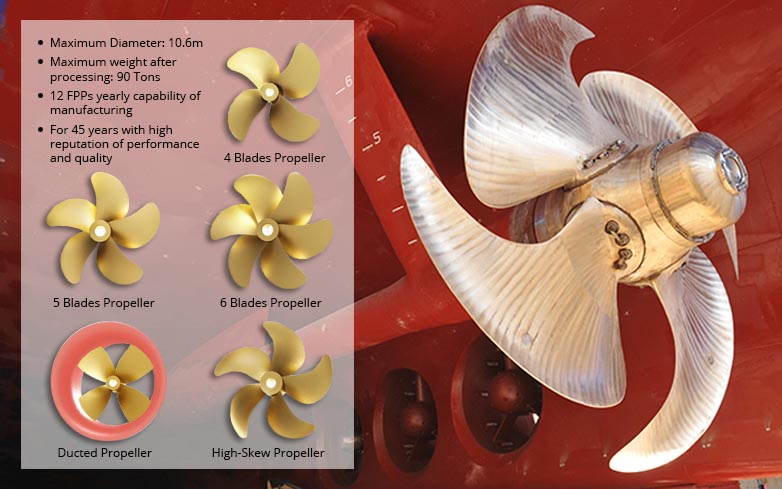

Welcome to our Bright Metal Works Propeller Works Portfolio, showcasing our comprehensive expertise in the design, manufacturing, and maintenance of propellers. With a rich history of innovation and excellence, we specialize in providing high-performance solutions tailored to meet the unique demands of both the aviation and marine industries.

- 4-Blade Propeller Design for Marine Applications

- 3-Blade Propeller Optimization for Aircraft

- Cutlass Rubber Bush Development

- Manufacturing Capabilities

- Maintenance and Repair Services

We successfully designed and developed a high-efficiency 4-blade propeller for a commercial shipping client by utilizing advanced CFD simulations to optimize blade geometry for maximum thrust and minimal cavitation, selecting high-strength stainless steel for its excellent durability and corrosion resistance, and conducting extensive sea trials that resulted in a 10% improvement in fuel efficiency and a significant reduction in noise levels.

Our team completed an optimization project for a 3-blade aircraft propeller, refining the blade shape and pitch to balance power output and fuel efficiency, and performing wind tunnel testing and in-flight evaluations that resulted in a 15% increase in overall efficiency and improved handling characteristics.

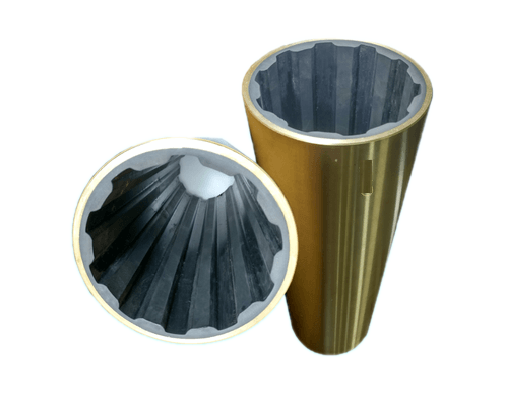

We developed and implemented a new cutlass rubber bush system for a naval vessel, ensuring superior shaft support and longevity by selecting advanced composite materials to withstand harsh marine environments and implementing precise alignment techniques to minimize wear and extend the service life of the propeller shaft system.

Our state-of-the-art manufacturing facilities are equipped with the latest technology, enabling us to produce high-quality propellers and components through precision casting and forging for robust and reliable propeller blades, and advanced CNC machining for accurate blade profiles and high-quality surface finishes.

We offer comprehensive maintenance and repair services to ensure your propellers remain in peak condition, including detailed inspections using advanced diagnostic tools to identify wear and damage, expert repair techniques such as welding, reshaping, and balancing to restore optimal performance, and regular preventive maintenance schedules to prevent issues and extend the lifespan of your propellers.

Web Admin | Terms & Conditions | Privacy Policy | Disclaimer

© 2018 All Rights Reserved | Design by Logic Events & Advertising